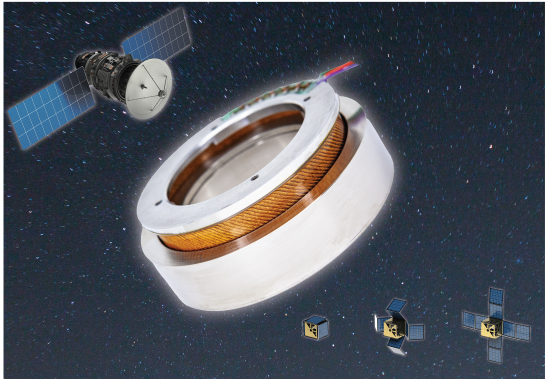

ThinGap has made available two new Space-rated frameless motor kits specifically designed for Reaction Wheel Assemblies (RWA) used to control small and miniaturized satellites. The new TGR 29-12 and TGR 45-20 are an extension of the widely used TG Series of aerospace motors supplied by ThinGap for nearly two decades. The vacuum compatible parts are 29mm and 45mm wide, and 12mm and 20mm tall, respectively.

ThinGap’s patented motor architecture has inherent advantages in RWA and flywheel applications: an efficient ironless core, zero cogging stator, high torque capacity, dynamic responsiveness, and overall weight savings.

The “air core” architecture lends itself to very low drag at high operating speeds and cogless torque. The wave-wound design of the stator produces a sinusoidal Back-EMF with total harmonic distortion of less than 1%. The precision hand wound coil results in a phase-to-phase balance within 1 degree. In combination, these produce the highest precision RWA motors available which yields essentially pure torque vector control with very low losses and zero cogging.

The new TGR’s design puts all the magnetics (the heaviest part of the motor) in the rotor, maximizing the inertia for a given weight and size. The resulting package is lighter weight for the same momentum storage capacity, and because of no iron saturation in the stator, ThinGap’s peak torque capacity is much higher than a similar weight motor. This gives a high dynamic response significantly better than the competition at a lighter weight. The motors are also highly efficient (up to 95%) since the architecture lends itself to very low drag at high operating speeds.

The TGR 29-12’s offers a continuous torque of 0.012 N-m and 0.0054 N-m/√W motor constant. The TGR 45-20 offers a continuous torque of 0.075 N-m and 0.0197 N-m/√W motor constant. This allows the new TGR motor kits to offer more than double the torque of the closest competitor with minimal losses.

Prior TG Series models have been widely used in RWA systems. Sample quantities of the new TGR 29-12 and TGR 45-20 are available with a 12 week lead time. Additional models of the TGR Series will include a 79 mm and 61 mm OD part set to be released later in 2022.

To learn more, click here.