ThinGap’s cogless motors have found success with novel and emerging applications due to their high efficiency, low-profile, smooth motion, and scalable architecture.

ThinGap’s zero-cogging, high performance motor kits are ideal for many aerospace and medical applications, such as gimbals, reaction wheel assemblies, and surgical robotics but are not limited to just these. Demand has also come from unique market segments, where customers with emerging applications like energy storage, submersibles and advanced generators need ThinGap’s slotless motors. Slotless motors offer the benefits of smooth, cogless motion and high efficiency, with custom and modified features allowing for deep integration.

Flight simulation and human interface applications desire low hysteresis and pure haptic feedback capabilities. Unmanned systems, whether airborne or underwater require high efficiency that equates to weight savings. Starter-generators provide a dual function in UAV applications, with high cranking capability to start the engine, and then high efficiency with a clean signal output as a generator. Submergible systems can benefit from the rugged nature of slotless motors and their inherent ability to be fully encapsulated as part of their normal fabrication process. Flywheel applications, whether the well-established use of momentum storage in Reaction Wheel Assemblies (small satellite attitude control) or larger-scale ones used for gyro-stabilization or energy storage benefit from high-speed operation, and the maximum amount of inertia for a given weight.

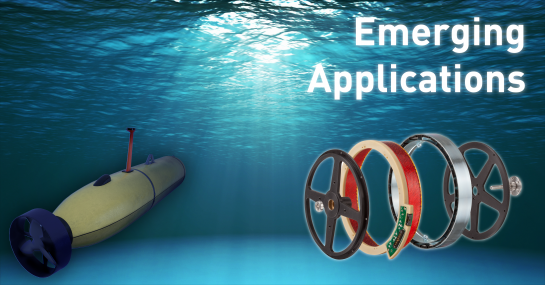

Unmanned Underwater Vehicles

An emerging use for ThinGap’s brushless DC motors is in underwater propulsion. ThinGap motors are ideal for underwater direct drive propulsion because of a high torque-to-diameter ratio. With no gearbox, there’s no drivetrain losses, lower assembly weight, increased torque, and greater reliability. Ring architecture allows propulsion to be directly outside of the rotor (propeller), or inside (impeller). High motor efficiency, low-noise underwater thrusters are ideal for the fast growing ROV, UUV, and AUV market segments.

Flight and Control Simulator Equipment

From aerospace to motorsports, simulation equipment is necessary to ensure immersion so professionals can hone their skills. ThinGap’s frameless architecture and smooth cogless motion makes it the ideal solution where a human operation or system need force sensing. Haptic systems require accurate torque feedback, without mechanical disturbances to improve the human control experience. ThinGap’s motor kits have near zero Eddy-current, low hysteresis, and a harmonic distortion of less than 1%, so torque output is directly proportional to current throughout the operating range.

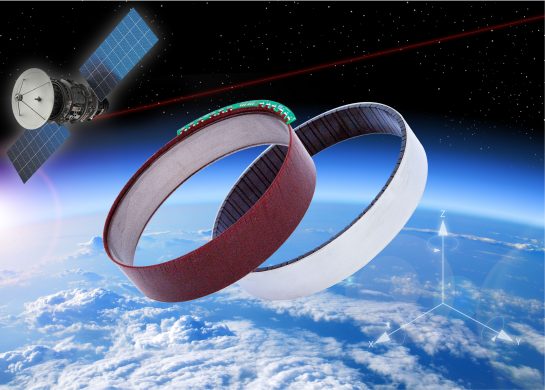

Flywheel and Energy Storage

The air-core architecture’s inherent high speed operation with high efficiency is why ThinGap motors are ideal for both energy generation and storage. Scalable to large sizes and high speeds while maintaining a high power-to-weight ratio as well as weight optimized components yields highly specialized mass profiles. Targeted flywheel applications include Space-rated Reaction Wheel Assemblies, gyro-stabilization for large spacecraft and marine vessels, or novel methods to store and generate power as part of a clean energy strategy.

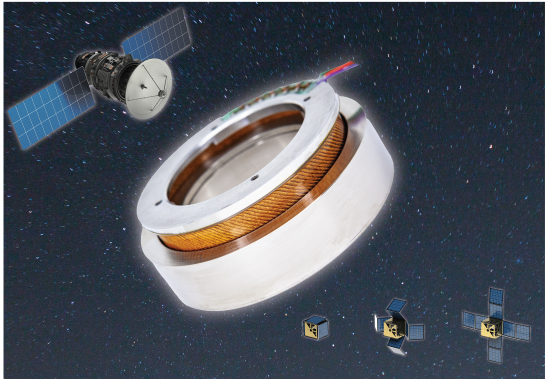

Starter/Generators

In both ground and airborne systems, as a starter-generator, ThinGap’s TG Series of air-core, impedance stators provide a stable, sinusoidal, low-droop voltage source and with an extremely high-power factor. ThinGap motors are a pure three phase voltage output with less than 1% harmonic distortion. In addition, with a large aperture architecture, affording the kit a thin radial cross section, so a large through hole and very lightweight with system efficiency of up to 95%.

To learn more about ThinGap’s motor kits, click here.