ThinGap’s space related business has been as strong as ever, and its no wonder why. According to market researcher McKinsey & Company, the space market was $447 billion in 2022, and their estimates put it at more than doubling to $1 trillion by 2030. The growth of the space market, previously the sole domain of wealthy nations, has been attributed in large part to the rapidly decreasing cost and frequency of vehicle launches coupled with the rising demand for intelligence, consumer internet, scientific observations, and high speed communications.

The single largest driver in the explosion of the space market can be attributed to the emergence of NewSpace, which summarily describes all private spaceflight efforts from corporate entities. NewSpace ventures include space tourism, provided by vehicles such as Blue Origin’s New Shepherd, and Virgin Galactic’s SpaceShip Two, as well as private launch vehicles such as SpaceX’s Falcon 9 and Starship and RocketLab’s Electron rockets. With the expansion of space flight and the related demand for applications tied to orbiting the Earth has come a significant increase in the need for systems, the largest being Low Earth Orbit (LEO) satellites.

Satellite constellations, much like their celestial counterparts, refer to a group of networked satellites working together for a common application, such as defense or telecommunications. The first constellation to be launched was the United States’ Global Positioning System, starting in 1978, which while initially used by the military, later became available for civilian use. Since then, many more satellite constellations have been launched, with a variety of applications such as communications, environmental monitoring, defense, and more recently internet constellations.

The ability to bring broadband connectivity to any point on Earth has been the mission of several internet constellations including SpaceX’s Starlink, Amazon’s Project Kuiper, and Airbus’s OneWeb programs. While most of these satellite constellations aren’t intended for end consumer use, Starlink is unique in that it’s possible to directly buy a receiver from SpaceX for personal use.

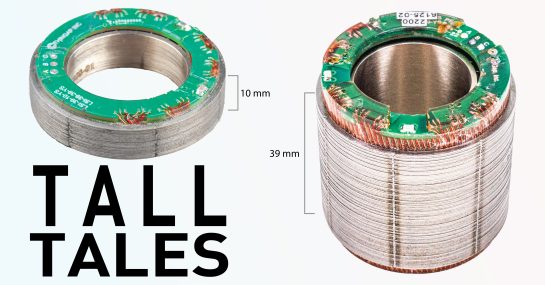

While all these constellations have varying missions and designs, there are common needs between the satellites that comprise them. Applications such as Attitude Control systems require high performance motors, with characteristics such as smooth motion, a lack of cogging, highly linear output, and a wide range of speeds, in addition to being lightweight, efficient, and reliable. ThinGap’s TGR Series is the industry’s first motor line designed from the ground-up for Reaction Wheel Assemblies (RWA), along with other ThinGap TG Series motor kits having spaceflight heritage.

Other critical space systems, such as Optical Communications Terminals, use highly collimated light generated by lasers to transmit data at high rates of speed over long distances through free space between satellite-to-satellite, satellite-to-aircraft, and satellite-to-ground. ThinGap’s LS Series of slotless motor kits is an industry leader for these gimbal applications requiring high performance and efficiency, decisive move-and-hold positioning, and smooth motion for long-range target lock.

Since 2015, ThinGap has supplied thousands of motors for space applications, including a major commercial internet constellation, as well as NASA. The company’s TG Series and LS Series both have significant space heritage and are ideally suited for a number of applications, mostly in satellites.