Fourteen seconds. That is the amount of time that the crew of Apollo 13 was instructed by NASA’s Mission Control to fire their Lunar Lander’s descent engine to return their damaged spacecraft back to Earth. With the ailing spacecraft being 60-80 miles off-course, this was the critical “push” that the crew needed to correct their return trajectory. The inside of the command module was close to freezing due to most onboard systems being shut down to conserve energy, including the onboard digital timer. With the odds stacked against the crew, it was up to a mechanical backup to time the engine burn – – Astronaut Jack Swigert’s Omega Speedmaster wristwatch. While the availability of a backup seems so obvious as to be an afterthought, it was in fact a decision that had been qualified by NASA five years earlier.

Flight qualification is a process by which components intended for space are subjected to a variety of conditions intended to replicate the harsh environment outside the atmosphere, not limited to vacuum, temperature, and shock. These tests are designed to push systems to their very limits to ensure functionality, an achievement that ThinGap motors have accomplished in support of an upcoming NASA mission. Qualifying anything for use in space, whether it be a ThinGap brushless DC motor or a commercially made Omega wristwatch, is an important and complex process.

The story of the watch that saved Apollo 13 began nearly a decade earlier, with Mercury-Atlas 8 in October 1962. In the early days of manned spaceflight, astronauts were not issued watches, and instead were permitted to wear their personal timepieces. For Mercury-Atlas 8, test pilot and astronaut Wally Schirra wore his Omega Speedmaster, beginning what became a long relationship between Omega Watches and NASA.

With America’s lofty goal of fulfilling recently assassinated President John F. Kennedy’s dream of landing a man on the Moon by the end of the 1960s, no detail was overlooked, including the astronauts’ watches. By the time NASA was ready to select a watch for the Apollo program in 1965, they issued a solicitation to a handful of watchmakers based off of astronaut feedback, with ultimately only three makers responding: Omega, Rolex, and Longines.

With the three brand of watches procured for evaluation, it came time to test them in the most scientific way possible… to destruction, with the following flight certification regiment having been pulled from historical documents:

-

-

- High Temperature– 48 hours at a temperature of 160°F (71°C) followed by 30 minutes at 200°F (93°C). For the high temperature tests, atmospheric pressure shall be 5.5 psi (0.35 atm) and the relative humidity shall not exceed 15%.

- Low Temperature –Four hours at a temperature of 0°F (-18° C)

- Temperature Pressure Chamber – pressure maximum of 1.47 x 10exp-5 psi (10exp-6 atm) with temperature raised to 160°F (71°C). The temperature shall then be lowered to 0°F (-18°C) in 45 minutes and raised again to 160°F in 45 minutes. Fifteen more such cycles shall be completed.

- Relative Humidity –A total time of 240 hours at temperatures varying between 68°F and 160°F (20°C and 71°C, respectively) in a relative humidity of at least 95%. The steam used shall have a pH value between 6.5 and 7.5.

- Pure Oxygen Atmosphere –The test item shall be placed in an atmosphere of 100% oxygen at a pressure of 5.5 psi (0.35 atm) for 48 hours. Performance outside of specification tolerance, visible burning, creation of toxic gases, obnoxious odors, or deterioration of seals or lubricants shall constitute a failure. The ambient temperature shall be maintained at 160°F (71°C).

- Shock –Six shocks of 40g each, in six different directions, with each shock lasting 11 milliseconds.

- Acceleration –The test item shall be accelerated linearly from 1g to 7.25g within 333 seconds, along an axis parallel to the longitudinal spacecraft axis.

- Decompression –90 minutes in a vacuum of 1.47 x 10E-5 psi (10 E-6 atm) at a temperature of 160° F (71° C), and 30 minutes at a 200° F (93°C).

- High Pressure –The test item shall be subjected to a pressure of 23.5 psi (1.6 atm) for a minimum period of one hour.

- Vibration –Three cycles of 30 minutes (lateral, horizontal, vertical, the frequency varying from 5 to 2000 cps and back to 5 cps in 15 minutes. Average acceleration per impulse must be at least 8.8g.

- Acoustic Noise –130dB over a frequency range from 40 to 10,000 HZ, for a duration of 30 minutes.

As if the torturous and destructive test routine wasn’t enough, the watches were subsequently required to retain their accuracy within 5 seconds a day. The Speedmaster was the winner by default, with the Longines and Rolex having failed at the beginning of the first temperature test. Despite being the victor, the Speedmaster was still worse for wear, with all the luminous paint on the dial having crumbled off, yet its workings remained accurate to within an impressive 4 seconds a day.

The Omega Speedmaster has changed very little cosmetically since it’s 1957 introduction

The reasons for the Omega Speedmaster’s durability ultimately comes down to a simple, yet robust mechanical movement inside, as well as a rugged, yet elegant case that envelops it. Introduced in the late 1950s for use in motorsports, the Omega Speedmaster is a hand-wound chronograph (a watch with an integrated stopwatch function) with a minimalist black dial with white markings and protected by a domed bubble acrylic watch glass. The Speedmaster had become a favorite amongst pilots due to the highly reliability, legibility, and most importantly, the accuracy it possessed.

Ed White on a spacewalk during Gemini 4

With the Speedmaster now qualified for all manned space missions and extravehicular activities, they became standard issue to NASA’s crews. In June 1965, Ed White wore his on the first American spacewalk during Gemini 4. When Apollo 11 landed on the Moon in July 1969, mission commander Neil Armstrong left his in the Lunar Lander to serve as a backup timer as the Lander’s internal electronic timer had malfunctioned. However, Buzz Aldrin chose to affix his for the moonwalk, making the Speedmaster the first watch worn on the Moon.

Buzz Aldrin in the Lunar Module ahead of lunar landing

Despite its previous widescale acceptance by the aeronautical community, the Speedmaster’s defining moment came during Apollo 13 in April 1970, after an exploded oxygen tank crippled the Apollo Lunar Module en-route to the Moon. With their vehicle critically damaged, making their lunar mission impossible, the astronauts agreed to forsake all creature comfort, and powered down all support systems, except for basic life support, including the digital mission timer to save power. Jack Swigert’s manual 14 second burn, timed on the watch, ensured that their freezing capsule re-entered the at the right angle, instead of their trajectory which would have bounced them off the Earth’s upper atmosphere and back into space.

Astronaut Jack Swigert during spacesuit fitment

The Speedmaster flew with NASA for the rest of the Apollo moon missions, and subsequent NASA programs. When Apollo-Soyuz, the first international space flight, flew in 1976, both the American astronauts and Soviet cosmonauts were seen wearing Speedmasters–an interesting detail given that cosmonauts had previously worn exclusively Soviet-made watches as a way to promote their domestic industry and were regularly worn aboard the Mir Space Station.

The Speedmaster was re-certified by NASA in 1978 for the Space Shuttle program, yet again undergoing the same rigorous regime. Through the Shuttle program, the Speedmaster remained standard issue for all astronauts, and in the 1990s, NASA and Omega collaborated on a clean-sheet watch, designed with the needs of modern astronauts in mind. This joint venture resulted in the Speedmaster X-33, which saw the purely mechanical watch upgraded to a modern, battery-powered computerized watch. Despite being superseded by a modern replacement, the original Speedmaster has still been seen worn aboard the International Space Station.

German Astronaut Alexander Gerst is seen wearing his Speedmaster X-33 aboard the International Space Station

To this very day, one can walk into a jeweler and buy a watch that is cosmetically and functionally identical to what has been flown since 1962. In fact, from the mid-1960s onward, the caseback of every Omega Speedmaster Professional (affectionately referred to as the Moonwatch) bears the inscription “Flight-Qualified By NASA In 1965 For All Manned Space Missions-The First Watch Worn On The Moon”.

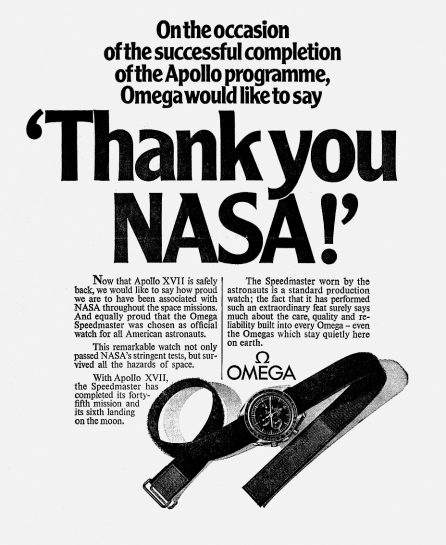

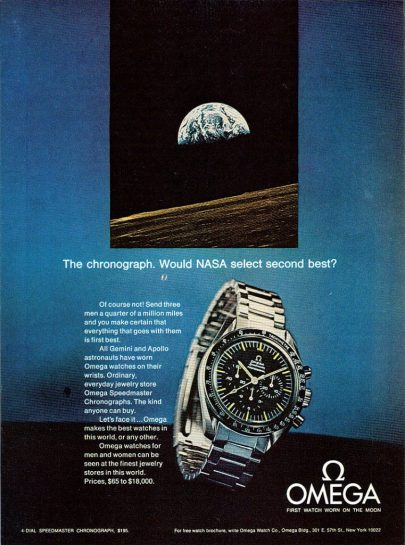

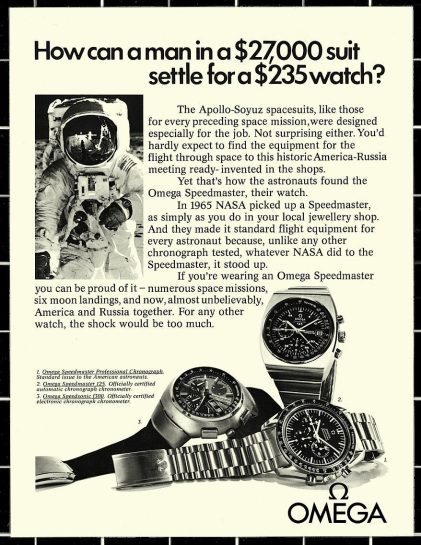

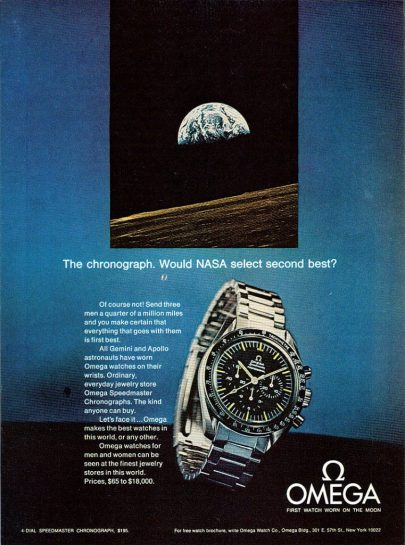

1970s Omega print ads detailing the Speedmaster’s involvement with NASA and the Apollo program

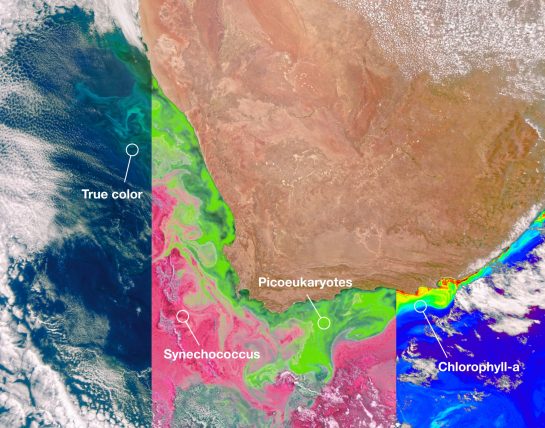

ThinGap has supplied flight-qualified motors to NASA in support of their upcoming PACE mission. Focused on monitoring the overall health of worldwide oceans and atmosphere by monitoring the color of the seawater, PACE is set to launch in February 2024 from Kennedy Space Center. ThinGap is honored to support this mission by supplying custom LS Series slotless motors that drive the satellite’s primary sensor, the Ocean Color Instrument. Additionally, ThinGap has supplied more than 2,500 motor kits in support of a major commercial constellation.

Works Cited:

OMEGA and Apollo 13 – The 14 critical seconds between success and failure

NASA Testing Regime for the Omega Speedmaster Moonwatch

Apollo 13 — A Life-Saving Fourteen-Second Burn Timed With The Omega Speedmaster Professional

A Watch Made for Space but Ready for Anything

Actual Pictures Actually Showing The Speedmaster Professional Actually Being Used For EVA, Today (Well, In 2014)

Watches used in space exploration