Product Release

Zero-Cogging and with a Low-Profile, the LSI 105-21 is the Latest Expansion to ThinGap’s Mid-size Motor Kits

With an outer diameter of 105 mm, and a 21 mm axial height, the LSI 105-21 provides 1.2 N-m of continuous torque output, yet only weighs 414 grams

The latest LS Series motor set uses a fiber-wound technique to bolster magnet retention of the rotor assembly

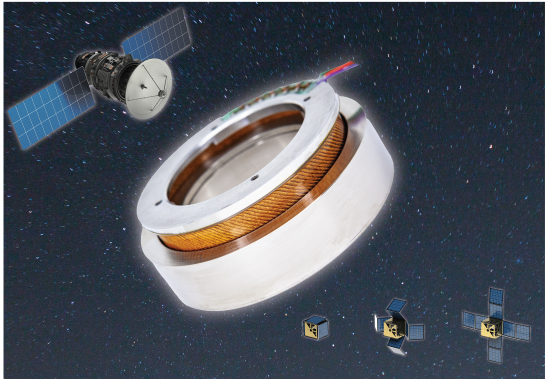

Camarillo, CA (May 31, 2024) – ThinGap continues to build out its LS Series of slotless motor kits with the latest release, the LSI 105-21. The new part has an outer diameter (OD) of 105 mm, and an axial height of 21 mm. With a maximum operating speed of 3,000 RPM, the LSI 105-21 has a 1-second peak torque output of 13.5 N-m, and a continuous one of 1.2 N-m.

Designed from the ground up, the LSI 105-21 was developed for use in space-based gimbals, such as Coarse Pointing Assemblies (CPAs) that perform critical laser-based satellite communications. All types of multi-axial gimbal systems can leverage the benefits of high-performance cogless motors, such as ThinGap’s LS Series, to directly drive movement and maintain position, while offering a large aperture and significant Size, Weight, and Power (SWaP) savings.

The LSI 105-21 marks the first time that an LS Series motor kit comes standard with a fiber-wound rotor. For high speed and fail-safe applications, ThinGap deploys a thin, but strong filament of epoxy-coated fiberglass over the magnets in building the rotor assembly. This enhanced rotor provides an additional safety margin called out by some customers.

ThinGap’s LS Series of slotless motor kits range in size from 25 to 267 mm diameter, and torque from 0.1 to 12 N-m continuous and voltages from 24-400 volts. Most LS motors are available with an optional space-rating that includes the use of low outgassing materials, leaded-circuit boards and a Materials and Processes (M&P) list that conforms to NASA’s standards.

Click Here to read the full press release.

Press Release

ThinGap Demonstrates High Power Capability with 45 kW Generator Assembly

Showcasing ThinGap’s highly adaptable technology, the TGD 129-114 introduces carbon fiber components for the most extreme TG Series part set ever made.

Designed for the high-power and high-speed required in UAV and other Airborne applications.

ThinGap has completed its latest high-power motor-generator prototype, the TGD 129-114, in support of a Government-funded defense program. In generator mode, the new assembly is designed for a steady 10 kW of power output at 7,000 RPM and is capable of 45 kW at 20,000 RPM. Mechanically, the TGD 129-114 has an outer diameter (OD) of 134 mm (5.28 in.), and an axial height of 124 mm (4.91 in.), making it about the same size as a coffee can.

Developed for use by the United States Army in airborne applications, namely Class II unmanned aerial vehicles (UAVs), the TGD 129-114 is the most radical evolution of the ThinGap TG Series to date. Designed for the extremely high continuous speed requirements typical in airborne generator applications, as well as being strength and weight optimized. Previous TG Series part sets have been used as starter-generators in other UAV platforms.

To minimize unit weight and maximize rotor inertia, the new assembly uses carbon fiber reinforced polymer (CFRP) for both the inner and outer sleeves that retrain the rotor’s magnets and are joined together by a purposely designed metallic top cap with fan blades that forces airflow across the stator. First developed in the late 1950s, CFRPs have become ubiquitous in demanding, high-performance applications such as aerospace and motorsports to reduce weight while not sacrificing strength.

The TGD 129-114 demonstrates ThinGap’s ability to deliver tailor-made high-power solutions. With more than two decades of experience in the design and production of slotless motor kits, ThinGap leverages its proven designs and analytical modeling that results in highly accurate transitions from predicted performance to real world operation. Furthermore, the process steps needed to produce motors of all sizes are highly scalable, and ThinGap has shipped large class motors with up to 400 kW of output power.

Click Here to read the full press release.

Product Brief

The TGR 60-30 is the Latest Release of a Purpose-Built, High Efficiency Motor

Designed for Reaction Wheel Assemblies (RWA) and Flywheel Applications

Optimized for maximum inertia, giving the greatest momentum for the least amount of mass

Specifically built for use in vacuum, making it space compatible by design

ThinGap has delivered to a commercial customer its latest purpose-built reaction wheel motor kit, the TGR 60-30. This newest motor kit has an outer diameter (OD) of 60 mm and an axial height of just 29.6 mm, providing a continuous in-vacuum torque output of 0.08 N-m, and a peak torque of 1.61 N-m. A complete datasheet is available on ThinGap’s website.

With a total part mass of 273 grams, the TGR 60-30 fits between the already released TGR 89-26 and TGR 29-12, showcasing the Company’s highly scalable stator architecture. In addition, the rotor of the TGR 60-30 is optimized for maximum inertia, giving the motor the greatest momentum for the least mass. As part of the industry’s first clean-sheet reaction wheel assembly product line, the TGR Series is designed for Attitude Control in SmallSat applications and other high precision systems.

Prior TG Series models have been widely used in Reaction Wheel Assemblies (RWA), due to the patented architecture’s inherent advantages when used in flywheel applications. Because of the efficient, lightweight ironless core, zero-cogging stator, and high power-to-weight ratio, the TGR 60-30 offers more than double the torque of the closest competitor with minimal losses and no radial forces between the stator and rotor.

With more than two decades of experience in the design and production of slotless motor kits, ThinGap can leverage proven designs and analytical modeling that results in highly accurate transitions from predicted performance to real world operation. Furthermore, the process steps needed to produce motors of all sizes is highly scalable; ThinGap has shipped motors from 25 mm up to 600 mm in size.

Click Here to read the full press release.

Product Brief

The new H-LSI 267-32 showcases ThinGap’s ability to engineer and deliver a fully-integrated Motor Assembly in a larger size than prior direct-drive designs

Designed around a low profile cogless motor with an optical encoder, precision bearing set, and anodized aluminum housing, the unit is for use in a ground-based NASA optical platform.

Camarillo, CA (November 28, 2023) – ThinGap recently shipped a housed version of its LSI 267-32 motor kit to a commercial customer in support of a ground-based NASA application, adding to the list of successful deliveries of housed units. Built around the company’s slotless 267 mm outer diameter BLDC motor kit, the H-LSI 267-32 integrates the high performance motor with a precision bearing set, and an optical encoder into a lightweight, chem film coated aluminum housing.

As a turnkey solution designed for a ground-based optical platform, this unit adds to ThinGap’s repertoire of housed and framed motor assemblies. The assembly measures 282 mm in diameter, with an axial height of 86 mm, and an internal aperture of 190 mm; the whole assembly weighs in at 8.34 kg (18.4 Lbs.), and produces a continuous torque output of 12.5 N-m, with a peak 1-second torque of 184 N-m.

Customers often come to ThinGap in need of a motor kit, wanting to take advantage of the low-profile, lightweight, and frameless architecture that is ideal for deep system integration. Yet, the time and cost of developing a housed solution are not lost on program managers and developers, so the availability of a ThinGap-led, fully engineered direct drive assembly provides a tangible advantage.

Beyond zero cogging, ThinGap’s air core motor kits have near zero Eddy current, and a harmonic distortion of less than 1%, so torque output is directly proportional to current. The resulting smooth motion and linear output makes them perfect for use in precision applications. ThinGap’s LS Series of slotless motor kits range in size from 25 to 267 mm in diameter, torque from 0.1 to 12 N-m continuous, and voltages from 24-400 volts.

Click Here to read the full press release.

Product Release

The new LSI 146-16 is ThinGap’s thinnest large-sized LS Series motor kit to date

With an outer diameter of 146 mm, the LSI 146-16 fits between the LSI 130 and LSI 152 motor kits

The axial height of the newest addition to the LS Series is only 16 mm tall

Camarillo, CA (September 16, 2023) – ThinGap continues to build out its LS Series of slotless motor kits with the latest release, the LSI 146-16. The new LSI 146-16 kit has an outer diameter (OD) of 146 mm, and an axial height of just 16 mm. With a total mass of just over 450 grams, it offers a continuous torque output of 1.48 N-m, and peak 1 second torque as high as 18.1 N-m.

Despite a maximum operating speed of up to 1,600 RPM, the LSI 146-16 was designed for use in slower speed gimbal systems, joining other LS Series models that have found uses in this application. Multi-axial gimbal systems leverage the benefits of high performance cogless Ring Motors, such as ThinGap’s industry leading LS Series, to directly drive movement and maintain position, while offering significant Size, Weight, and Power (SWaP) savings.

Using its proprietary thin wire-wrapped stators and optimized permanent-magnet rotors, ThinGap provides motors with specifications that can match the torque output of slotted motors, while avoiding the cogging, size and weight penalty that plagues them. ThinGap’s LS Series of slotless motor kits range in size from 25 to 267 mm diameter and torque from 0.1 to 12 N-m continuous and voltages from 24-400 volts.

Click Here to read the full press release.

News Brief

THINGAP WELCOMES VISITORS FROM NASA GODDARD SPACE FLIGHT CENTER

Left to Right-Joseph Kay, PhD-Director of Engineering, John Baumann, President, and Robby Estep and Dustyn Strosnider from NASA Goddard Spaceflight Center

This past week, ThinGap hosted visitors from NASA who delivered their appreciation for the support of their PACE mission. The team from NASA Goddard gave a progress update on the mission, as well providing a Certificate of Appreciation that the ThinGap team can proudly display. NASA’s PACE mission is focused on monitoring the overall health of worldwide oceans by monitoring the color of the water, as well as atmospheric observation. ThinGap is honored to support this mission by supplying custom LS Series slotless motors that drive the satellite’s primary sensor, the Ocean Color Instrument. NASA’s PACE Spacecraft is schedule to launch from the Kennedy Space Center in January 2024.

Product Release

The New LSI 85-13 Slotless Motor Kit Set to Take Flight

Designed with airborne gimbals in mind, this new variant builds on the LS Series’ flight heritage

The 85mm OD fills the gap between the LSI 75 and LSI 105 standard models

ThinGap continues the expansion of its LS Series of slotless motor kits with the latest release, the LSI 85-13. The new LSI 85-13 motor kit has an outer diameter (OD) of 85 mm, and an axial height of just 13 mm, making it a little wider than 3 inches and roughly half an inch tall. With a total mass of 232 grams, it offers a continuous torque output of 0.324 N-m and a peak as high as 3.88 N-m.

The LSI 85-13 can operate at speeds of 0-1,760 RPM. Unique to the cogless nature of ThinGap’s slotless architecture, all of its motor kits can effectively operate across its entire range of speeds. Effective low speed is due to not needing to overcome the detent torque typical in a slotted or stepper motors.

Designed from the ground up for use in a gimbal system, the LSI 85-13 joins other ThinGap motors that have found homes in airborne applications. Multi-axial gimbal systems leverage the benefits of high performance cogless Ring Motors to directly drive movement and maintain position, while offering Size, Weight, and Power (SWaP) savings, which are all highly desirable traits. ThinGap’s LS Series of slotless motor kits is an industry leader for gimbal applications.

Using its proprietary, thin wire-wrapped stators, and optimized permanent-magnet rotors, ThinGap provides motors with specifications that can match the torque output of slotted motors, while avoiding the cogging that plagues them. ThinGap’s LS Series of slotless motor kits range in size from 25 to 267 mm diameter and torque from 0.1 to 12 N-m continuous, voltages from 24-400 volts, and current from 1 to 100 amps.

Click here to read the full press release.

Press Release

ThinGap Renews ISO 9001:2015 Certification Until 2026

Renewal for three more years underlines ThinGap’s commitment to stringent customer quality requirements and the widely recognized ISO Standards

Camarillo, CA (March 28, 2023) ThinGap’s ISO 9001:2015 certification has been renewed for another three years, and will remain in effect until March 2026. An audit and renewal of ThinGap’s certificate was completed by American Global Standards, LLC of Montecito, CA as the basis for the Certification renewal.

Based on ISO 9001:2015, ThinGap’s Quality Management System (QMS) serves as the baseline for delivering high quality products to many customers with program-specific QC requirements for a wide variety of industries. ThinGap has a track record of supporting the exacting requirements for its base of Fortune 500 companies, Government customers, including NASA, and regulatory specifications across multiple sectors, be it space, medical, defense or airborne.

To read the full press release, click here.

Product Brief

ThinGap Demonstrates High Power Motor Capability with 100 kW Motor Kit

Showcasing ThinGap’s highly scalable slotless motor technology, the TGO 385 was designed with renewable energy in mind, but many potential applications exist.

Camarillo, CA (February 13, 2023) ThinGap has completed its latest large-size motor prototype, the TGO 385 for a commercial customer. The TGO 385 motor kit has an outer diameter (OD) of 385 mm (15 in.), and an axial height of 223 mm (9 in.), making it about the same volume as a 5-gallon bucket. The power output capability of the TGO 385 is estimated to be 100 kW or more depending on the application.

Showcasing the highly scalable nature of ThinGap’s motor architecture, the TGO 385 is the newest variant of the TG Series of slotless motor kits. The company’s TG motors are unique in having a stator architecture with an ironless coil. Due to the absence of slots or “teeth”, ThinGap’s stators do not saturate during operation, allowing the motor kit to produce more torque as current is applied, without the falloff seen in traditional iron core motors. Combined with a mechanical design that promotes convective cooling during operation means that the TG Series has unrivaled power density.

The TG Series has been successfully used in a wide variety of generator, propulsion, and flywheel applications, ranging from gyro-stabilization in boats and satellites to airborne starter-generators. To learn more the highly efficient, zero-cogging TG Series of slotless motor kits, click here.

The TGO 385 demonstrates ThinGap’s ability to deliver tailor-made high-power solutions. With more than two decades of experience in the design and production of slotless motor kits, ThinGap leverages its proven designs and analytical modeling that results in highly accurate transitions from predicted performance to real world operation. Furthermore, the process steps needed to produce motors of all sizes is highly scalable, and ThinGap has shipped large class motors of up to 600 mm OD, ranging from 10-400 kW of output power.

To read the full press release, click here.

Product Brief

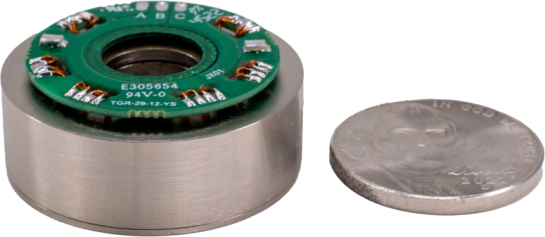

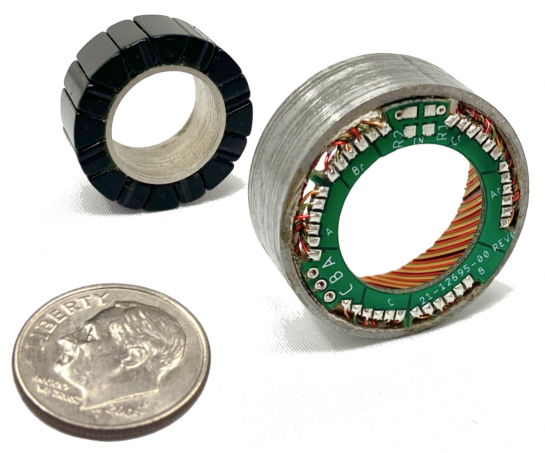

ThinGap Demonstrates Small Motor Capability with the Delivery of its TGR 29-12

With the smallest stator yet, the TGR 29-12 demonstrates the scalability of ThinGap’s slotless motor technology

Camarillo, CA (December 27, 2022) ThinGap has delivered its latest small-size product, the TGR 29-12, to several commercial customers. The TGR 29-12 motor kit has an outer diameter (OD) of 29 mm and an axial height of just 12 mm, providing a continuous in-vacuum torque output of 0.0028 N-m, and a peak torque of 0.034 N-m. A complete datasheet is available on ThinGap’s website.

With a total part mass of 31 grams, and a coil OD of 19.2 mm, the TGR 29-12 has the smallest stator of any ThinGap motor to date, showcasing the company’s highly scalable architecture. Designed for Attitude Control in CubeSat applications, the new part continues the build out of the Space focused TGR product line.

Prior TG Series models have been widely used in Reaction Wheel Assemblies (RWA), due to a patented architecture’s inherent advantages when used in any type of flywheel applications. Because of the efficient lightweight ironless core, zero-cogging stator, and high power-to-weight ratio, the TGR 29-12 offers more than double the torque of the closest competitor with minimal losses and no radial forces between the stator and rotor.

With more than two decades of experience in the design and production of slotless motor kits, ThinGap can leverage proven designs and analytical modeling that results in highly accurate transitions from predicted performance to real world operation. Furthermore, the process steps needed to produce motors of all sizes is highly scalable; ThinGap has shipped motors from 19 mm up to 600 mm in size.

For additional information on custom motor development, please contact the company at [email protected].

To read the full press release, click here.

Product Release

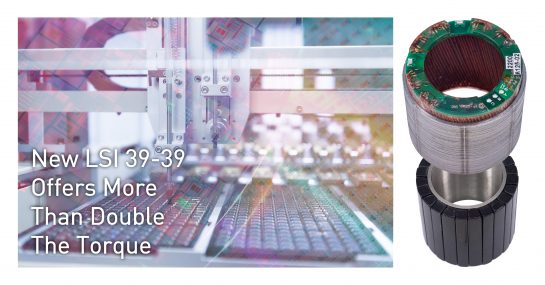

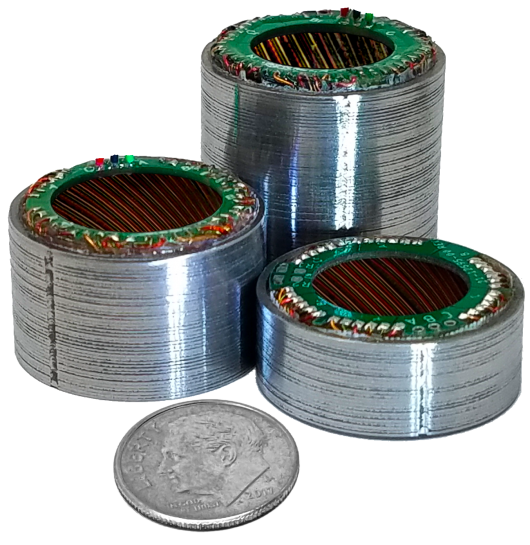

ThinGap Marks the First Customer Deliveries of the Newest LS Series’ 39mm by 39mm Cogless Motor Kits

A new, taller variant of the LSI 39 frameless motor kit now means three sizes with a 39mm OD

Unique in that the part it is as tall as it is wide, resulting in very high torque despite its small size

Camarillo, CA (September 13, 2022) ThinGap has delivered the first production units of its newest LSI 39 motor kits to customers. The new LSI 39-39 motor kit has an outer diameter (OD) of 39mm and also an axial height of 39mm; the height is more than double that of its sister product the LSI 39-17, and nearly quadruples that of the LSI 39-10. This increase in axial height more than doubles the continuous and peak torque outputs to 0.279 N-m and 1.020 N-m, respectively, compared to the LSI 39-17.

The LSI 39-39 can operate at speeds from 0-4,600 RPM and has a motor constant of 0.05 Kt. Thanks to the LS Series’ steel lamination stack architecture that retains the highly precise wave-wound stator coil, all LS products provide an excellent thermal path when clamped or bonded as part of system integration.

ThinGap’s customers for the LS and TG Series of motor kits consistently take advantage of the product lines’ inherent zero cogging motion, low profile and large through hole. The architecture of both product series yields a highly linear torque output, and little or no hysteresis.

The LSI 39-39, like all the small to medium-sized LS products is targeted at torquer motor applications in robotics, gimbals, and precision industrial systems, including semiconductor production and metrology equipment. With outer diameter sizes from as small as 25mm, and up to 267mm, the LS line ranges in continuous torque from 0.1 N-m up to 12.0 N-m. Standard, modified, and full custom designs are available in both in-runner and out-runner configurations.

To read the full press release, click here.

Press Brief

ThinGap Demonstrates Cybersecurity Compliance with NIST 800 Certification

Camarillo, CA (July 28, 2022) – As an example of an ongoing commitment to supporting customers in all markets, ThinGap was recently certified by the Department of Defense’s Military Critical Technical Data Agreement program through the NIST 800-171 Cybersecurity Survey protocol. Designed for Prime Contractors and their Subcontractors who perform under US Department of Defense contracts, internal computer networks must be found to be in compliance with Federal Acquisition Regulation (FAR) and Defense Federal Acquisition Regulation Supplement (DFARS) standards.

The NIST 800-171 is a Department of Defense protocol outlining computer network security to ensure safety of Controlled Unclassified Information (CUI). Suppliers are required to assess their network security under these protocols and submit their findings to be eligible for Government contracts and solicitations.

Serving as a supplier to many different Prime Contractors, and directly to Government Agencies, NIST 800-171 certification highlights ThinGap’s commitment to the US Space and Defense industries.

Press Release

ThinGap Joins Allied Motion, Becoming “Center of Excellence”

In a merger transaction, ThinGap becomes a wholly-owned legal entity within Allied Motion, with ThinGap shareholders becoming Allied Motion shareholders.

Camarillo, CA (May 24, 2022) – ThinGap has announced that it will become a “center of excellence” within Allied Motion, and expects to leverage their global capabilities and complementary technologies. In a stock-merger transaction, ThinGap shareholders will become shareholders in Allied Motion, and in turn ThinGap contributes its patented technology and proven track record of motor design, quick-turn production, and sustaining support for key customers.

ThinGap’s strength in supporting the Aerospace, Medical and Precision Industrial markets is a solid fit within Allied Motion’s portfolio, and expanding to new ones not currently covered by ThinGap.

Allied Motion is a well-established, publicly traded company (NASDAQ: AMOT) offering a wide range of motion control solutions, including electro-magnetic, mechanical, and electronically controlled motion technologies. Founded in 1939, Allied Motion is headquartered in Amherst, NY, and has worldwide operations.

John Baumann, CEO of ThinGap, commented, “The ThinGap and Allied Motion combination is powerful, and I am excited for what we will accomplish together. ThinGap’s highly engineered products and focus on top tier OEM customers will benefit from Allied’s complementary product offerings, broad sales channels, and volume manufacturing capabilities. I consider becoming part of Allied Motion to be very strategic, and beneficial to all ThinGap stakeholders, including our customers and employees.”

Mr. Baumann will remain on as the leader of the standalone business unit, as will all other ThinGap employees. No change is expected to the group’s ongoing emphasis on design, engineering, and manufacturing at its Camarillo, CA location.

ThinGap’s motors come in a wide range of sizes, power output, and form factors ideally suited for high-end applications, such as satellites, airborne systems, optics platforms, test equipment, and medical robotics. ThinGap’s market leading products are expected to expand Allied Motion’s precision motion capabilities, all while providing integrated motion solutions. The combined entities have the potential to advance the company’s capability in the robotics, semiconductor, and instrumentation markets, where ThinGap’s slotless motor characteristics are well suited.

To read the full press release, click here

Press Release

ThinGap Participates in the 37th Space Symposium

Annually held in Colorado Springs, CO, Space Symposium is widely known as the premier U.S. Space policy and program forum for all sectors of Space

Product Release

The Industry’s First Application-Specific Reaction Wheel Motor Line

The “TGR” Series of High Efficiency, High Inertia, Ironless-Core Motors

ThinGap’s patented motor architecture has inherent advantages in RWA and flywheel applications: an efficient ironless core, zero cogging stator, high torque capacity, dynamic responsiveness, and overall weight savings.

The “air core” architecture lends itself to very low drag at high operating speeds and cogless torque. The wave-wound design of the stator produces a sinusoidal Back-EMF with total harmonic distortion of less than 1%. The precision hand wound coil results in a phase-to-phase balance within 1 degree. In combination, these produce the highest precision RWA motors available which yields essentially pure torque vector control with very low losses and zero cogging.

The new TGR’s design puts all the magnetics (the heaviest part of the motor) in the rotor, maximizing the inertia for a given weight and size. The resulting package is lighter weight for the same momentum storage capacity, and because of no iron saturation in the stator, ThinGap’s peak torque capacity is much higher than a similar weight motor. This gives a high dynamic response significantly better than the competition at a lighter weight. The motors are also highly efficient (up to 95%) since the architecture lends itself to very low drag at high operating speeds. Prior TG Series models have been widely used in RWA systems. Sample quantities of the new TGR 29-12 and TGR 45-20 are available with a 12 week lead time. Additional models of the TGR Series will include a 79 mm and 61 mm OD part set to be released later in 2022.

Press Brief

ThinGap Demonstrates Large Motor Capability with the Delivery of its LSO 393

Product Release

New 39 mm-Sized LS Motor Kits, Available in Three Axial Heights

Like all ThinGap motors, aside from being cogless, the stator windings are very thin and the rotor is optimized, resulting in a precision movement within a low-profile form factor with a very large through-hole.The LS line of torquer motors is being widely used in gimbals, optics, robotics and precision industrial applications that need cogless movement and are also looking for efficiency, low harmonic distortion, highly linear torque output and a compact form factor.“The addition of a new smaller-sized set of motor to the LS Series really helps fill out the lower end of the product line,” said Joseph Kay, Director of Engineering at ThinGap. “We continue to establish ourselves as the market leader for slotless motor kits and assemblies, whether as part of our Standard Products or commonly modified-standard, and custom designs.”This new variant of the LS fits in between the already established LSI 25 and LSI 51 motors sized motor sets and is part of the ongoing addition of variants within ThinGap’s LS product line. The LS Line of is ideally suited for smooth and precise motion in targeted applications in the typical aerospace, medical, precision industrial and communications markets. With OD sizes from as small as 25 mm and up to 267 mm, the LS line range in continuous torque from 0.1 N-m up to 12 N-m.

Like all ThinGap motors, aside from being cogless, the stator windings are very thin and the rotor is optimized, resulting in a precision movement within a low-profile form factor with a very large through-hole.The LS line of torquer motors is being widely used in gimbals, optics, robotics and precision industrial applications that need cogless movement and are also looking for efficiency, low harmonic distortion, highly linear torque output and a compact form factor.“The addition of a new smaller-sized set of motor to the LS Series really helps fill out the lower end of the product line,” said Joseph Kay, Director of Engineering at ThinGap. “We continue to establish ourselves as the market leader for slotless motor kits and assemblies, whether as part of our Standard Products or commonly modified-standard, and custom designs.”This new variant of the LS fits in between the already established LSI 25 and LSI 51 motors sized motor sets and is part of the ongoing addition of variants within ThinGap’s LS product line. The LS Line of is ideally suited for smooth and precise motion in targeted applications in the typical aerospace, medical, precision industrial and communications markets. With OD sizes from as small as 25 mm and up to 267 mm, the LS line range in continuous torque from 0.1 N-m up to 12 N-m. Capabilities Update

ThinGap Staff Renews and Expands its Annual IPC J-STD Training

ThinGap is ISO 9001:2015 certified and supports customer-specific flow downs as part of program compliance and its Quality Management System. Industry-leading process and workmanship standards, such as IPC J-STD for soldering, are used throughout the production process. The annual training and certification of the J-STD is a key aspect of ThinGap’s quality control.IPC is the global association that helps manufacturers and electronics industry suppliers build electronics and electronic components to higher standards. Like in years’ past, ThinGap production staff as well as quality control personnel underwent training to the IPC J-STD-001 specification. J-STD-001, is the Requirements for Soldered Electrical and Electronic Assemblies and the preeminent standard for electronics assembly manufacturing. The standard describes materials, methods, and verification criteria for producing a broad range of high-quality interconnections and emphasizes process control.Workmanship standards, such as IPC J-STD and others like the American National Standards Institute or “ANSI” standards, are used throughout ThinGap’s production process. Furthermore, all documents and procedures are controlled by the Company’s Product Lifecycle Management (PLM) system.

ThinGap is ISO 9001:2015 certified and supports customer-specific flow downs as part of program compliance and its Quality Management System. Industry-leading process and workmanship standards, such as IPC J-STD for soldering, are used throughout the production process. The annual training and certification of the J-STD is a key aspect of ThinGap’s quality control.IPC is the global association that helps manufacturers and electronics industry suppliers build electronics and electronic components to higher standards. Like in years’ past, ThinGap production staff as well as quality control personnel underwent training to the IPC J-STD-001 specification. J-STD-001, is the Requirements for Soldered Electrical and Electronic Assemblies and the preeminent standard for electronics assembly manufacturing. The standard describes materials, methods, and verification criteria for producing a broad range of high-quality interconnections and emphasizes process control.Workmanship standards, such as IPC J-STD and others like the American National Standards Institute or “ANSI” standards, are used throughout ThinGap’s production process. Furthermore, all documents and procedures are controlled by the Company’s Product Lifecycle Management (PLM) system. Press Brief

ThinGap Announces Delivery of its new LSI 267-58 Motor Kits to Customers

Camarillo, CA (December 6, 2021) – ThinGap has delivered the first production units of its new LSI 267-58 motor kits to commercial customers. The new LSI 267-58 motor kit has an outer diameter (OD) of 267 mm and an axial height of 58 mm, nearly double that of its smaller counterpart motor, the LSI 267-32. The new LSI 267-58’s increase in axial height more than doubles the continuous torque output to 24.4 N-m, up from 11.5 from the LSI 267-32. In addition, peak torque has grown three-fold, from 68.1 N-m to 191.0 N-m.

The outer diameter of the LSI 267 motor kits is approximately 10.5 inches across, making it the same size as a small pizza. The LSI 267 kits are targeted at in gimbals and industrial applications that need cogless movement and are also looking for highly linear torque output, a low profile and a large through hole.

Click here to view the full press release

Product Release

The new LSO Series of “Out-Runner” Motor Kits Now Available

Camarillo, CA (September 1, 2021)– ThinGap has made available two new variants of its successful LS Series of torque motor products: the LSO 225-51 and LSO 225-66. The new parts are 225 mm wide and either 51 or 66 mm tall, respectively. Using an outrunner architecture (where the rotor revolves on the outside, as opposed to the inside of the stator), the new motor kits offer a mechanical feature that is beneficial to applications needing outside rotation around a stationary center. Prior custom LSO models have been developed for use in gimbals and satellite-based laser communication systems.

Click here to view the full press release

Press Release

ThinGap Attends 36th Space Symposium

Camarillo, CA (August 27, 2021) – ThinGap participated in the 36th Space Symposium in Colorado Springs on August 24-26, 2021. The company was represented at the show by its CEO, John Baumann and Matt Panesis, its lead Applications Engineer. Additional members of ThinGap network of sales representatives were present at the show. In addition to meeting potential customers, domestic and international Space agencies, and industry partners, ThinGap proudly demonstrated a working unit of its recently released H-LSI 75-12, a turnkey Direct Drive Motor Assembly based on the company’s slotless motor technology.

Click Here to view the full article

Press Release

ThinGap Completes Delivery of Motor Kits to NASA

Camarillo, CA (June 7, 2021) – ThinGap has announced the final delivery of flight-grade motor kits to NASA in support of their PACE Program’s Ocean Color Instrument (OCI). ThinGap’s motor technology has been used in commercial, scientific, and military Space-grade systems that are now in orbit.

“PACE” is NASA’s Plankton, Aerosol, Cloud, ocean Ecosystem satellite mission to observe global ocean biology, aerosols, and clouds. It is scheduled to launch in 2022. “OCI” is the satellite’s primary sensor, specifically a spectrometer used to measure intensity of light over portions of the electromagnetic spectrum. As a high-precision optical platform, OCI will enable continuous measurement of light at finer wavelength resolution than previous NASA ocean color sensors.

Click here to view the full article

Tech Demonstrator

Direct Drive Motor Featuring ThinGap’s Slotless Technology

Camarillo, CA (May 25, 2021) – ThinGap has made available a Direct Drive Motor assembly intended as a Technology Demonstrator and featuring LS Series of slotless motors. Using a low profile, 150 gram, 75 mm-OD motor kit, the new “H-LSI 75-12” includes ThinGap’s high-performance cogless motor, a precision bearing set, and a 20-bit absolute encoder from Renishaw. The part aims to demonstrate the superior performance of ThinGap’s motor technology and offers customers a chance to purchase the assembly as a test unit, demonstrator, in support of rapid prototyping, or even low-rate production applications needing a turnkey solution.

Click here to view the full Article

Market Focus

Medical and Robotics

Camarillo, CA (April 9, 2021) – Today’s modern Robotic Systems and Collaborative Robots, including robotically assisted surgical-systems, require smooth precision motion in their robotic joints and end-effectors. Haptic systems require accurate torque feedback without mechanical disturbances to improve the human control experience. Multi-axis robots in manufacturing and semiconductor applications need low profile, frameless kits that fit inside articulating wrists, elbows, and shoulder axes while having high torque and low heat.

Click here to view the full Market Focus

Application Note

High Efficiency, Precision Motor Kits for Spacecraft Attitude Control

Camarillo, CA (February 12, 2021) –The rapid deployments of cost-effective Low Earth Orbit (LEO) satellites, including “CubeSat” microsatellites, is being driven by the demand for global broadband communications, scientific missions, and the Military’s ongoing critical intelligence objectives. Whether commercial or defense in nature, these spacecrafts need Attitude Control that enables high accuracy pointing capabilities so that desired objects of interest, point-to-point communication or optical platforms can be effectively utilized.

Click here to view the full Application Note

Product Release

Twice the height and speed, the new LSI 59-22 is part of an Ongoing product line expansion

Camarillo, CA (January 26, 2021) – ThinGap has begun the expansion of the LS series of slotless motor kits with taller variants, starting with the release of the LSI 59-22. The LSI 59-22 has an outer dimension (OD) of 59mm and axial heights of 22mm. Like all ThinGap motors, the stator is very thin and the rotor is optimized, resulting in an overall low profile motor with a very large aperture. Both the LS and TG Line of slotless motor kits feature high-performance, zero cogging, high efficiency, and are lightweight.

Click here to view the full press release

Product Release

ThinGap presents the LSI 25-16 and LSI 25-25

Camarillo, CA (October 26, 2020) – ThinGap has announced an expansion to its smallest ever motor kit, the LSI 25-10. This ultra-small 25 mm outer diameter (OD) class of motors now has the option for 16 mm and 25 mm tall variants, which boast increased torque and power within the same small profile. The new LSI 25-16 and LSI 25-25 are part of the ongoing addition of “tall” variants to all sizes within ThinGap’s LS product line. Expected to be released by early 2021, the LSI 51-13 and LSI 59-13 are the next motor kits to receive tall variants.

Click here to view the full press release

Press Release

Delivery of Slotless Motor Solutions to NASA and US Navy

Camarillo, CA (September 10, 2020) – ThinGap has announced the recent delivery of high-performance motors to NASA and the Navy, under separate projects. As a USA-designer and maker of electric motors, ThinGap is especially proud of the support it has provided to these and other Agencies.

Government customers represent a small, but important, aspect of ThinGap’s motor development and production business targeted at aerospace, industrial, and medical applications. Its zero cogging, high efficiency and lightweight architecture has many uses in the areas of military, energy, and space.

Click here to view the full Press Release

Technology Brief

Understanding Torque Ripple and its Impact on Coggless Motors

Camarillo, CA (August 7, 2020) –ThinGap’s aerospace, medical and industrial customers demand high-torque, high-efficient, yet zero cogging motor solutions. Zero-cogging is a key and inherent feature of ThinGap’s precise stator wrappings and slottless architecture. But beyond the motor’s core design, in order for customers to achieve the performance advantages of smooth, coggless motion, integration factors like drive electronics need to be considered. Torque ripple is one important factor to be aware of.

Click here to view the full Technology Brief.

Product Release

ThinGap presents its Newest Motor, the LSI 25-10

Click here to view the new LSI 25-10 motor specs

Camarillo, CA (May 27, 2020) – ThinGap has announced its smallest ever motor kits, the LSI 25-10. This ultra-small 25 mm outer diameter (OD) class of motors is an expansion of the now established LS Series of slotless motor kits and is about the size of a 1” hose clamp. The LSI 25-10 is the first released part in the planned 25 OD-sized motor offerings by ThinGap. By the third quarter of 2020, the LSI 25-10 is expected to be joined by two taller designs, the LSI 25-16 and LSI 25-25 (16 and 25 mm axial heights, respectively).

Click here to view the full press release

Press Release

ThinGap Renews ISO 9001:2015 Certification

Enhanced Quality System now supporting wider base of end-applications

Camarillo, CA (March 28, 2020) – ThinGap, Inc. announced that its ISO 9001:2015 certification has been renewed for another three years and will remain in effect until March 2023. An audit and renewal of ThinGap’s certificate was completed by American Global Standards, LLC. ThinGap has also completed a comprehensive review of its Quality Manual and its standard quality and deliverables policy as part of its ongoing commitment to continuous improvement and building customer satisfaction.

Click here to view the full press release.

Product Release

ThinGap Sampling its Newest Motor, the LSI 75-30 “Tall”

Click here to view the LS-Series

Camarillo, CA (April 8, 2020) – ThinGap has announced the latest expansion to its LS Line of slotless motor kits with the addition of the taller version of its LSI 75 parts. The radius of all the LSI 75’s is about the size of a soda can’s rim and is now available in three different heights, a short 12 mm version (LSI 75-12), a tall version at 20 mm (LSI 75-20) and the newest addition, an extra tall 30 mm height (LSI 75-30).

Click here to view the full press release.

Press Release

ThinGap Completes Production Floor Expansion

Thirty percent increase in production floor space and added headcount

Building lease commitment extended through December 2022

Camarillo, CA (August 2, 2019) — ThinGap Inc, has confirmed the completion of a recent production floor expansion, along with a hiring plan that expands its build capacity by 30%. The expansion and staffing of additional assembly, solder, and test workspaces addresses an uptick in business and the launch of a new product line, the LS Series.

Click here to view the full press release.

Press Release

ThinGap and Sierramotion to work on Integrated Slotless Motor Applications

Collaboration of ThinGap’s Zero Cogging Motor Kits and Sierramotion’s Motion System Expertise

Camarillo, CA (June 14, 2019) — ThinGap Inc. and Sierramotion Inc. have begun working on ways in which the two companies can collaborate in finding integration opportunities for ThinGap’s high-torque, slotless motor kits. Sierramotion specializes in designing turn-key mechatronic (mechanical, electrical and control) solutions for its clients. In many robotic, imaging, medical and precision manufacturing applications, Sierramotion would expect to integrate ThinGap’s zero cogging slotless motor kits into their designs resulting in smooth and precise motion, while still being highly-efficient.

Click here to view the full press release.

Press Release

ThinGap Renews ISO 9001:2015 Certification

Enhanced Quality System now supporting Large Commercial Space Program

Camarillo, CA (April 30, 2019) — ThinGap Inc announced that its ISO 9001:2015 certification has been renewed for another year and will remain in effect until May 2020. An annual audit and renewal of ThinGap’s certificate was completed by American Global Standards, Inc.

Click here to view the full press release.

Press Release

ThinGap Names New CEO with High-Tech Background

Experience in Operations, Business Development and Finance

Camarillo, CA (January 16, 2019) — ThinGap Inc announced that John Baumann has joined the company as its new Chief Executive Officer. Mr. Baumann will lead ThinGap’s management team in setting strategy and financial direction while actively participating in operations and business development.

Click here for the full press release.

LS Series Motors

ThinGap, Inc has released a new product family called the LS series. The LS series of motors is designed specifically to meet the demands of low speed, high torque dense applications in a frameless configuration. The LS line, due to ThinGap’s no-cog design, is ideal for use in gimbals, robotics and other high precision positioning applications. We have several products available for off the shelf purchase with more coming this year. Custom options are also available. More details on the product family and the available motors can be found here: https://www.thingap.com/ls-series-motor/

In addition to this new series release ThinGap’s TG line is ever expanding. New motors are available and can be found here:

https://www.thingap.com/tg-motor-series/

ThinGap is constantly engaged in new research and development. Projects planned or in the works include:

1. ThinGap Space – ThinGap already has motors in space. Look for expansion of space ready designs including space ready gimbal motors and reaction wheel motors.

2. Axial flux motor series – An axial flux configuration of ThinGap technology for applications where axial flatness is key

3. Linear motor series – An unwrapped version of ThinGap’s technology for 3 phase high precision linear actuation

4. ThinGap EVTOL – High power, full scale EVTOL motors for long range EVTOL with high power, torque, and efficiency dense motors in the 200kW-500kW range

5. ThinGap Hybrid – High power generators for hybrid electric aerospace applications 200kW-500kW capacity

6. ThinGap MegaWatt – Motor and generators with megawatt capacity

Stay tuned for more product updates from ThinGap!!

Regards,

ThinGap Team

4035 Via Pescador,

Camarillo, CA 93012

For sales or technical inquiries contact:

Dr. Joseph Kay

[email protected] or [email protected]

or visit our contact page:

https://www.thingap.com/contact-thingap