With a focus on providing engineered solutions for a variety of high performance applications, ThinGap regularly provides modified versions of its off-the-shelf motor kits to meet customer specifications. Many of these changes include switching a motor’s winding configuration, space rating, high-temperature capability, or custom mounting configurations to create a modified-off-the-shelf product. In some cases, customers request an increase in axial height of an existing motor to improve the torque output of the motor kit without increasing the width.

Important to note that with ThinGap’s proprietary slotless motor architecture, torque increases exponentially with the outer diameter, but only proportionally with axial height. So while a larger outer diameter motor is always the better choice, customers often have mechanical constraints that limit their ability to accept a wider motor, making a taller product the next best solution.

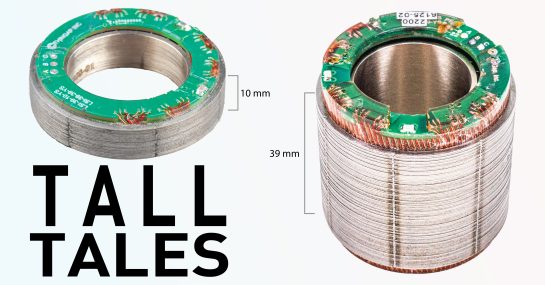

ThinGap’s tooling is vertically modular, making it simpler and less expensive to change the axial height of a kit to improve torque output. Tall variants share much of the same material components with their smaller cousins, and can in many case be built in parallel. Many of ThinGap’s tall motor variants began as modified-custom solutions, such as the LSI 39-39, LSI 75-30, LSI 130-40, LSI 152-55, and LSI 267-58. By way of example, several motors sizes offer three different axial highest, such as the LSI 25 that is available in axial heights of 10, 16 and 25mm.

With two decades of experience in the design and production of slotless motor kits, ThinGap leverages its proven designs and analytical modeling that results in highly accurate transitions from predicted performance to real world operation. Furthermore, the process steps needed to produce motors of all sizes are highly scalable and ThinGap has standard products as small as 25mm, up to 393mm in outer diameter.

For a complete listing of our standard products, including our tall variants, please click here.