As the primary feature and the focus of ThinGap’s product lineup, a lot has been spoken about zero cogging torque in the product lineup. Cogging torque is the interaction between the permanent magnets in the rotor, and the slots of the stator. Because the rotor magnets are attracted to the stator teeth, the torque required to move the rotor changes with the relative position of the rotor to the stator. In other words, additional energy is required to break the position dependent detent torque to advance the motor.

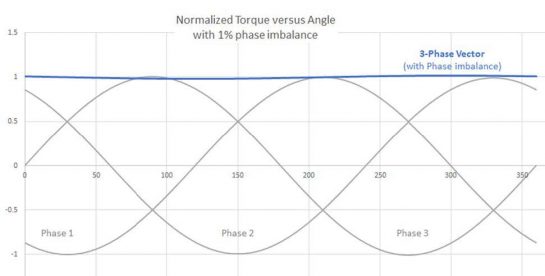

Cogging torque adds harmonic content to the torque-versus-angle curves for each phase. When driven by a sinusoidal current, harmonic content of the torque-versus-angle curves cause undesirable variations in torque production that interfere with smooth motor rotation. Additionally, phase imbalance common in a traditional slotted motor can further exacerbate the issue. The result is a phenomenon known as torque-ripple which is a variation of torque production with position.

There are a few issues when trying to integrate a traditional cogging motor into an application that requires precision actuation. To mitigate cogging torque in a slotted motor, it is possible to design the lamination stack with a rotational skew, so the magnetic field of the stator is diagonal to that of the magnetic field of the rotor. Alternatively, the magnets can be designed with a skew. Other techniques include using different slot-pole combinations and compensating for cogging and phase imbalance in the drive electronics.

However, when integrating slotted motors into systems for precision actuation, there will always be issues. Due to the nature of manufacturing, there is always variance between two seemingly identical motors, which can have an unpredictable impact on the cogging profile and phase balance. Furthermore, solutions to minimize cogging torque typically reduce the total output of the motor. The sunk cost of trying to mitigate cogging torque on both motor costs and development labor is better spent on the correct solution: slotless, coggless, brushless DC motors from ThinGap.

The benefit of ThinGap slotless and ironless motor designs is that they eliminate cogging torque by design. Their uniquely constructed phase windings produce a balanced phase amplitude and angle relationships between phases. This results in less than 1% total harmonic distortion of the back EMF waveform which minimizes torque ripple when paired with sinusoidal drive electronics.

ThinGap’s slotless motor architecture with wave-wound coils prevents cogging since the air-core rotor has no slots. Wound around a flat bobbin with a basket weave style winding, ThinGap’s composite air core motor kits have no iron. The thin nature of the coils produces very high copper packing and a motor with a large through hole, up to 80% of the outer diameter. In addition, ThinGap’s motor kits are available with Halbach array rotors, optimizing the magnetic flux for the highest torque density in a slotless motor.

To learn more about zero-cogging motion solutions, please contact us.