From aerospace to motorsports, many industries rely on ThinGap’s cogless motor technology. One of the largest applications for ThinGap’s patented motor technology has been active control systems for satellites. Satellites of all sizes require the ability to control their orientation in orbit, what is referred to as “Attitude Control.” Whether commercial or defense in nature, LEO spacecrafts need Attitude Control that enables high accuracy pointing capabilities so that desired objects of interest, point-to-point communication or optical platforms can be effectively utilized.

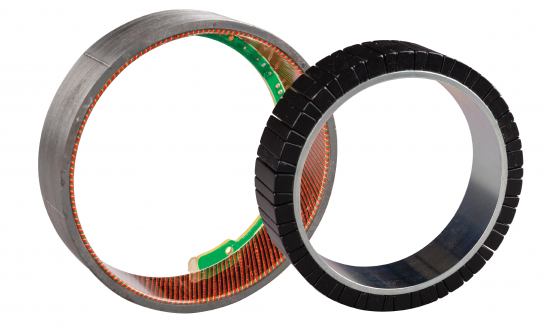

Active control systems, such as Reaction Wheels Assemblies (RWA) and Control Moment Gyroscopes (CMG), require highly efficient motors for torque and actuation. With two lines of high performance slotless motors — both with space heritage, ThinGap’s cogless motor technology is well suited for these Attitude Control solutions.

Here are the top five reasons why ThinGap is the industry leader for RWA and CMG motors.

- HIGH EFFICIENCY | For reaction wheel motors, ThinGap supplies ironless or “air core” stators made of fine stranded wire for the coil. This lends itself to very low drag at high operating speeds, with a significant improvement over traditional iron core slotted motors. Additionally, the torque capacity is increased across the full operating range for the same momentum storage capacity.

- HIGH TORQUE AND INERTIA-TO-WEIGHT RATIOS | ThinGap’s ironless stator puts all the magnetics, the heaviest part of the motor, in the rotor. This maximizes the inertia for a given weight and size requirement. The reaction wheel’s necessary flywheel mass can be reduced, and sometimes fully incorporated into the rotor. The resulting package is lighter weight for the same momentum storage capacity.

- HIGH PRECISION | ThinGap’s motors use a wave-wound coil, which results in a back EMF that is sinusoidal with a total harmonic distortion of less than 1%. When paired with a sinusoidal drive, torque ripple is minimized and much lower than similar motors. Additionally, the ironless stator produces absolutely zero cogging motion. In combination, these aspects produce the highest precision RWA motor available.

- DYNAMIC RESPONSE | Due to no iron saturation in the stator, ThinGap’s peak torque capacity is much higher for a similar weight motor. This gives a dynamic response significantly better than the competition at a lighter weight.

- COMPLIANCE AND CAPABILITY | ThinGap designs and builds its motors in the USA and provides highly engineered solutions and program support. Since 2015, thousands of Space-grade or MIL-STD rated motor parts have shipped for use in commercial satellites, UAVs, military aircraft, and NASA flight programs.

The TG Series‘ and TGR Series‘ high-speed, high-efficiency is ideal for momentum-wheels in both RWA and CMG. The LS Series’ high-torque, lower-speed precision movement is perfect for gimbal applications, like those in a CMG architecture and related Satcom and Optical applications.

Since 2015, ThinGap has shipped thousands of space-grade or MIL-STD rated motor parts for use in commercial satellites, UAV, military and commercial aircraft, and flight-grade NASA programs.